Leading Provider of MTO Engineering Services and Olefin Separation Technology Licensing

Wison Engineering is one of the leading providers of Methanol-to-Olefins (MTO) engineering services and olefin separation technology licensing. With more than 16 years of continuous practice in MTO plant engineering and R&D in olefin separation technologies, we have developed a complete system that covers licensing of MTO olefin separation technology, process package development, full-plant engineering design, procurement, construction, and digital delivery. This mature system is supported by extensive project execution experience.

We hold independent intellectual property rights in MTO olefin separation technology. Our proprietary "pre-cut & oil absorption" separation process is a core innovation, offering lower capital investment, reduced energy consumption, higher product recovery, and proven process reliability. We have granted twelve technology licenses, including applications in the world's largest million-ton-per-year MTO complex. In engineering services, our robust quality and HSE management systems ensure high-quality delivery that has been widely recognized by our clients.

Wison Engineering entered into a global collaboration agreement with Honeywell UOP in 2017. Leveraging UOP's advanced MTO/OCP technology together with Wison's proprietary olefin separation technology, we jointly provide MTO technology and full EPC services worldwide, offering the best solution to clients with maximized commercial value, high ethylene and propylene yields, and low energy consumption.

Wide propylene/ethylene ratio

Propylene/ethylene ratio (P/E) = 1.0~1.5

More Efficient Catalyst

Utilizes SAPO-34 molecular sieve, resulting in fewer by-products. Lower catalyst consumption of 0.16 ~ 0.20 kg/t methanol

Integrated with advanced OCP process

Efficient cracking of C4+ by-products to maximize ethylene and propylene yields

2.5~2.55 ton methanol/ton olefins

Higher reaction pressure (0.28~0.3 MPa) (the 2nd-generation MTO reaction technology)

Smaller reactors and therefore lower investment (12% less compared with low pressure design case)

Higher inlet pressure of MTO product gas compressor and lower overall energy consumption

Advanced "pre-cut & oil absorption" separation technology (the 3rd-generation MTO separation technology)

Higher ethylene and propylene yields (≥99.80%)

Lower energy consumption (5~10% lower)

Higher propane purity and higher propane production

Recover DME to increase olefin yields

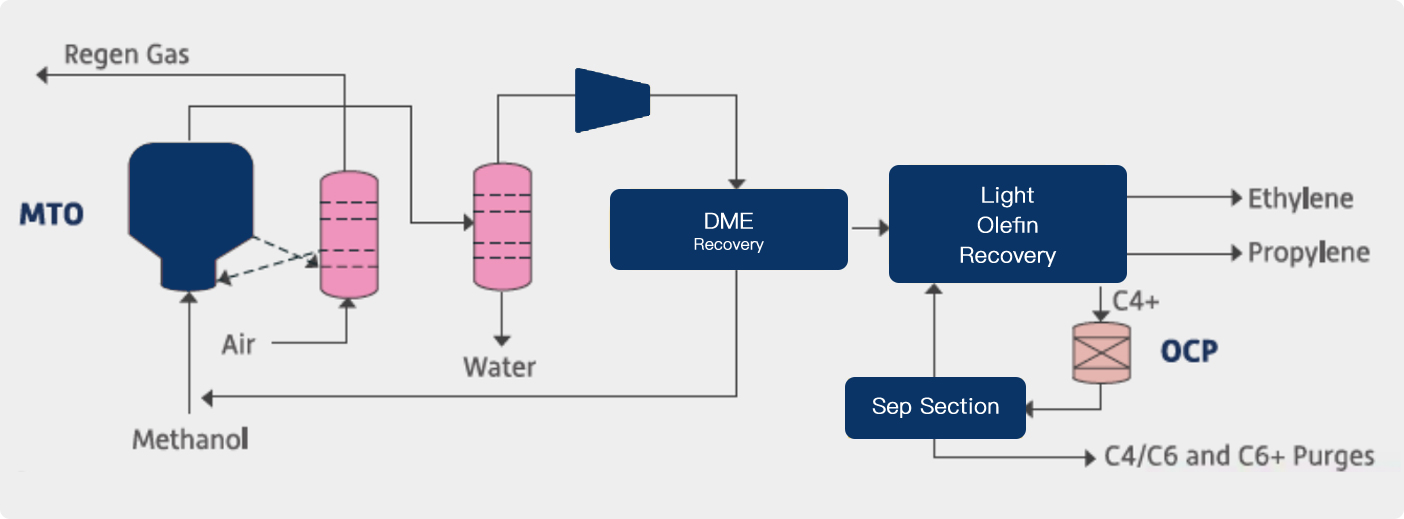

Typical Advanced MTO/OCP (the 2nd-generation MTO reaction technology) Flow Diagram

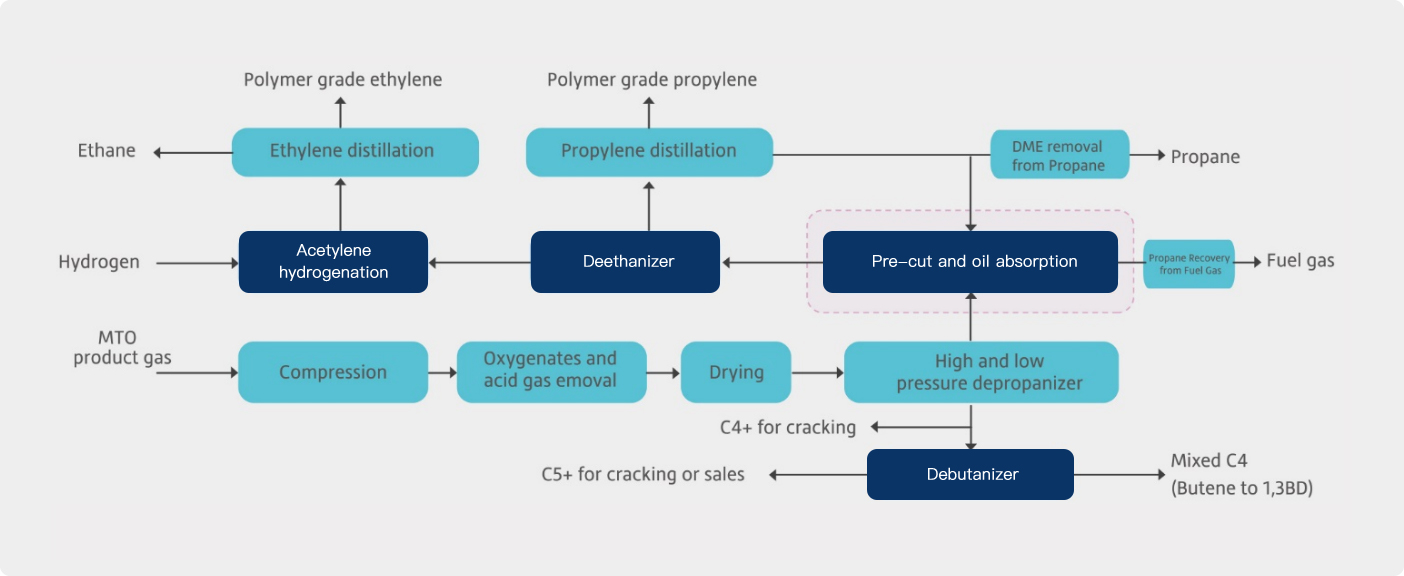

Wison MTO Olefin Separation Process Block Flow Diagram (the 3rd-generation MTO separation technology)

(Mixed C4 can be processed by Wison's proprietary oxidative dehydrogenation technology for producing butadiene to maximize profit)

300 KTA, 600 KTA and 1,000 KTA MTO olefin separation technology licensing and PDP delivery

FEED and engineering design of the whole MTO unit

Well-rounded EPC capability

Commissioning and start-up service

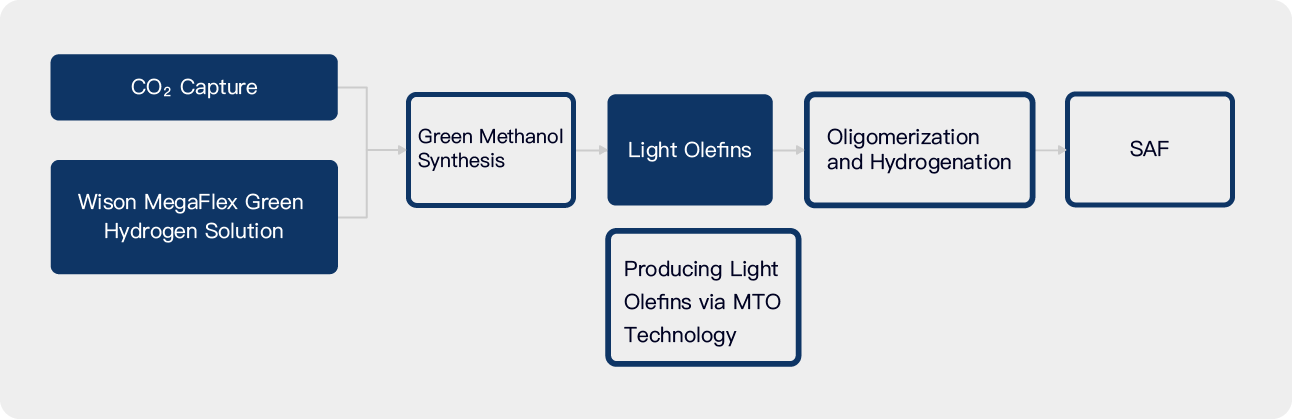

Green Methanol-to-Sustainable Aviation Fuel (SAF)

The demand for sustainable aviation fuel (SAF) is rising rapidly. Compared to conventional jet fuel, SAF can cut CO emissions by over 80% and is a key enabler for the aviation industry to achieve net-zero emissions by 2050. Global demand is expected to reach around 3.5 million barrels per day by 2030‒2050. Expanding renewable feedstock sources is essential to long-term decarbonization.

Green methanol, synthesized from green carbon sources and green hydrogen, is a critical feedstock route. MTO plays a pivotal role in converting green methanol to SAF. Light olefins are first produced through MTO, and then oligomerized and hydrogenated to yield hydrocarbon products with carbon distribution matching aviation fuel standards. This enables the production of high-quality SAF.

Our client is committed to replacing traditional fossil fuels with clean energy, focusing on green hydrogen as a core feedstock to achieve sustainable development between new energy and green chemical products. One of our clients is developing a 1,000 KTA biomass methanol project with a 100 KTA green methanol-to-SAF facility. Powered by abundant wind energy resources, the project will produce high-quality SAF via UOP's new process using green methanol as feedstock, advancing the latest decarbonization practice in aviation. This initiative supports the client's green transition and contributes to the low-carbon future of aviation.

Contact Us

If you would like to learn more about Wison Engineering's engineering services and technology integration solutions.

Please click the button below to contact us, and our team will provide you with professional consulting services as soon as possible.

Leave us a message