A Turnkey Green Hydrogen Solution Provider

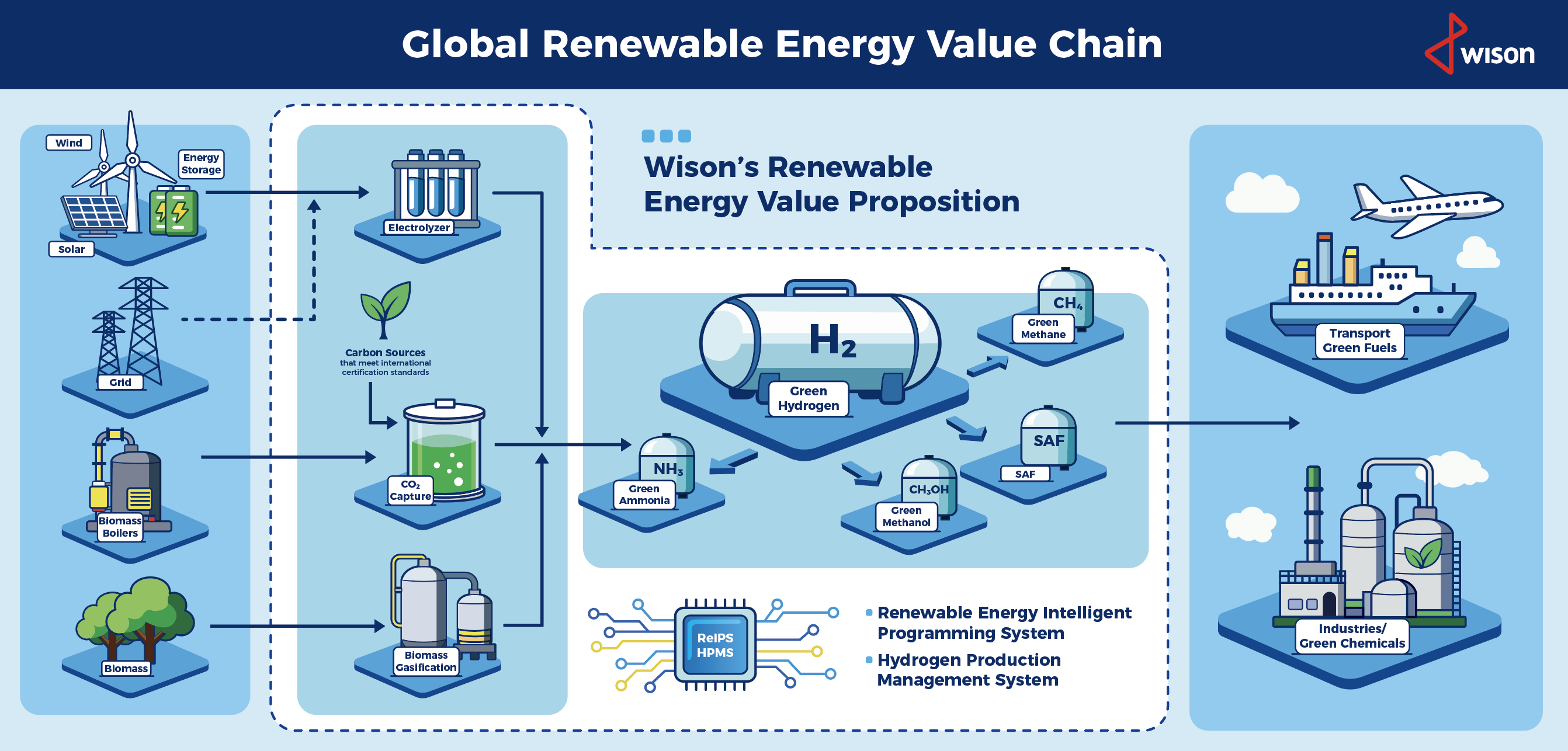

Leveraging its full life-cycle engineering expertise, Wison Engineering delivers turnkey services that cover every stage from design to construction. With a “Technology + Engineering” approach at its core, Wison’s New Energy business is dedicated to providing comprehensive, end-to-end industrial solutions — from the MegaFlex “Plant-as-a-Product” green hydrogen system to downstream applications such as green ammonia, green methanol, and sustainable aviation fuel (SAF) — empowering global clients to advance toward a more sustainable energy future.

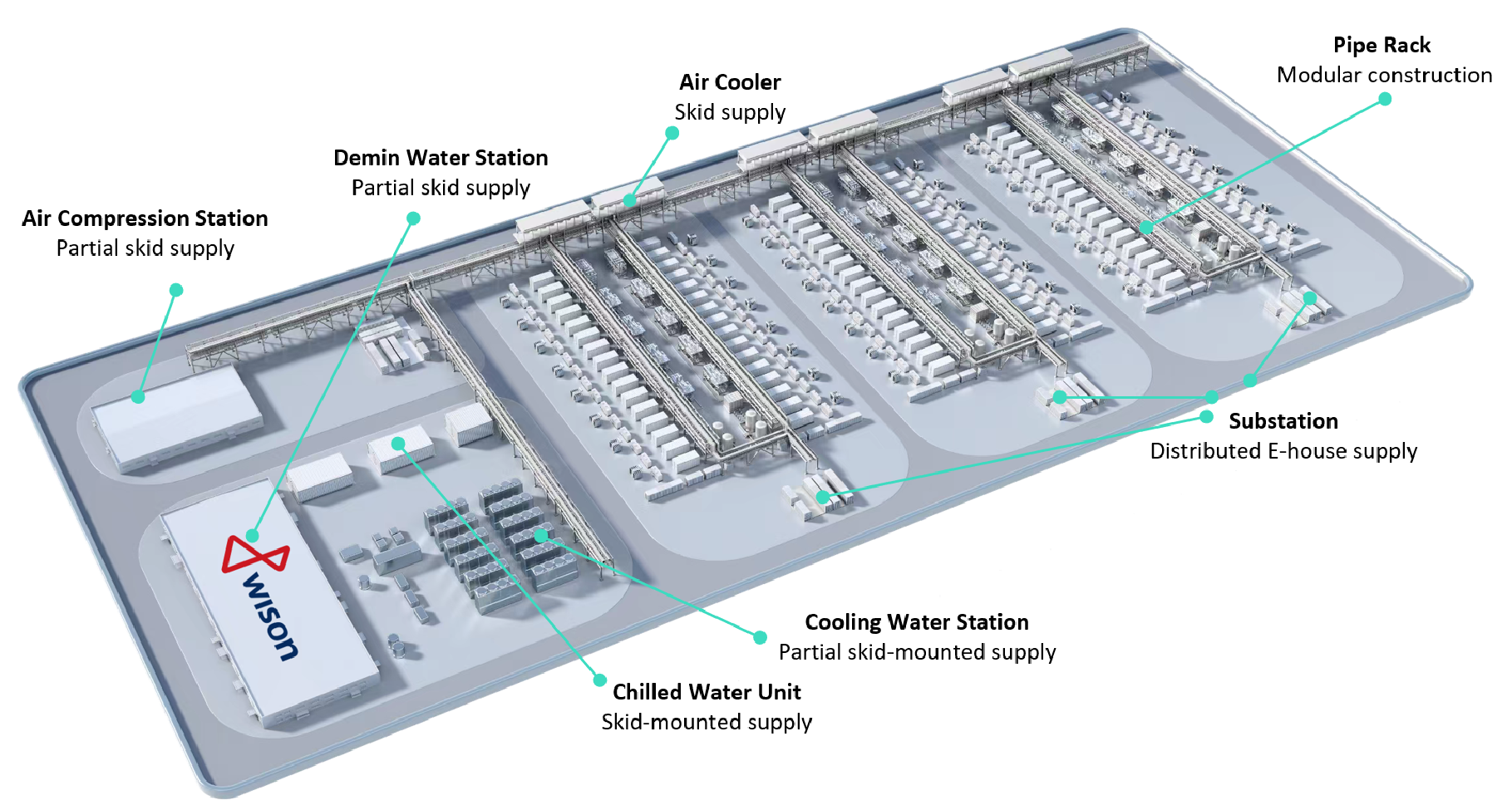

MegaFlex is Wison Engineering's integrated turnkey solution for green hydrogen production, developed based onthe "Plant-as-a-Product" concept and incorporating Sungrow Hydrogen's leading electrolyzer technology.

Leveraging Wison's proven track record and modular delivery capabilities in energy engineering projects, MegaFlextransforms green hvdrogen plants from traditional engineering proiects into standardized, replicable, scalable, anorapidly deployable products. This approach ensures safe, stable, and reliable operation of large-scale projects whiletargeting lower levelized cost of hydrogen (LCOH) and accelerating project delivery.

Beyond hydrogen, MegaFlex can be extended to ammonia, methanol, methane, and sustainable aviation fuel (SAF).enabling integrated planning and co-design across the full value chain. By doing so, it provides systematic,sustainable clean energy solutions, offering global customers a safer, more efficient, and more cost-effectivepathway to clean energy.

| Product Series | MegaFlex 100 | MegaFlex 500 |

|---|---|---|

| Product Series | MegaFlex 100 | MegaFlex 500 |

| Rated Hydrogen Flow | 1798kg/h | 8990kg/h |

| Hydrogen Purity | 99.999% | 99.999% |

| Hydrogen Pressure | 16barg | 16barg |

| Operating Temperature | 90±5℃ | 90±5℃ |

| Plant Efficiency@BoL | 52.1kWh/kg | 52.0kWh/kg |

| Operating Range | 10-110% | 10-110% |

| Footprint-Hydrogen Production | 0.8ha | 3.5ha |

| Footprint-Plant | 1.8ha | 7.8ha |

| Sound Pressure Level | 85dB at 1m | 85dB at 1m |

| Ambient Temperature | -20°C~+40°C | -20°C~+40°C |

| Cooling Water 32-42°C | 2400t/h | 12000t/h |

| Chilled Water 7-12°C | 180t/h | 860t/h |

| Purified Water | 16t/h | 81t/h |

| Instrument Air | 300Nm3/h | 700Nm3/h |

| Nitrogen | 200Nm3/h | 260Nm3/h |

| Standards | ISO22734-2019; GB; ASME; NFPA 2; IEC; CE Certification | |

Standardized, Serialized

The MegaFlex solution is architected for hydrogen plants across multiple capacities. Through solution optimization, its standardized design enables rapid configuration and deployment with minimal adaptations when addressing custom requirements.

Intelligent

MegaFlex integrates Wison's proprietary ReIPS intelligent simulation platform, enabling configuration optimization and control strategy adjustments based on upstream renewable data, downstream demand, and operational requirements, thereby optimizing both CAPEX and OPEX.

Modularized

Wison delivers highly modularized, plantwide facilities through advanced engineering capabilities in modular planning, design, and end-to-end execution. This modular approach reduces on-site construction costs and shortens project duration.

Comprehensive Turnkey Solutions for Green Hydrogen and Its Applications

Contact Us

If you would like to learn more about Wison Engineering's engineering services and technology integration solutions.

Please click the button below to contact us, and our team will provide you with professional consulting services as soon as possible.

Leave us a message